So you have bought your first bow! Or maybe you are looking at 2 or 3 options to finally start shooting those dragons. But how to know if what you are looking at and considering is of quality worthy of your hard-earned money?

Well below I try and list some examples of what makes a bow reliable and quality by just looking at it. You may find some very well made gear that doesn’t have to cost too much. Just be aware of the little tell-tale signs that can let you know if a bow was well constructed or not.

I am sure I will have missed some bits and pieces so please feel free to add suggestions. So Let’s get started!

First and foremost, Bows from all around the world are created in similar and yet different ways.

For fibreglass or wooden bows the process is very similar but materials/recipes and skills used can vary immensely.

What makes a Quality Fibreglass Bow

This type of bow is really hard to quality control without looking under the leather that is used on the limbs. Most fibreglass bows are constructed with some ornament or wrap around each limb to embellish the look of the bow. Underneath these wraps most fibreglass bows have a light green to grey tinge. I am not recommending you look at each of your fibreglass bows by stripping away the cover as most times they are glued on and you may end up damaging the wrap.

Starting tips: String your bow and pull it back to around 28 inches. Here are some factors to look for to determine the quality of your bow:

- Are there any loud cracks as you pull back? Not the light glue cracks but a loud crack as you pull back.

- At what point does it start stacking? This is when the bow grows in weight more and more rapidly as you pull it back. Think of lifting a brick from your hip to above your head. Does it get harder as you lift it or is it a smooth transition of your arm?

If the bow was well made and the right resins and fibreglass were used then there should be a smooth pull from when you start, to 28 inches without the draw getting suddenly heavier.

Usually a good resin bow becomes suddenly heavier at around the 26 inch mark. This means that the bow’s maximum power starts at 26 Inches and the more you draw the more power you get but it also becomes exponentially heavier. Remember to not overstretch the bow as they are mostly designed with a safe limit of 30 inches.

- Is the leather work a nice, vibrant leather/suede/material or is it a dull dye that feels cheap to the touch? You can tell the quality of a good leather by the thickness and the softness/feel that it has in your hands. The image below is an example of quality leather.

- The last factor to look for before you peel the wrap back is to align one end of the bow to your eye and look down the string towards the other end. If there are bends or warps from end to end, then the bow is not straight. This will result in unreliable shooting and possible problems of the strings coming off as you shoot which can be very dangerous.

Once you pull off the wrap you will be able to tell the colour of your fibreglass and resin along with some other bits and bobs:

- Are there streaks in the glassing/resin work? If there are streaks, as the picture below, then it means that the bow maker couldn’t really be bothered creating a nice finish and sanded the glass too fast which “melted” a little amount of it and created a streak. This can happen with any glassing if you sand it fast and it becomes too hot.

- If there are any micro cracks it also means that the bow may have been dry fired or under some severe stress in the shipping/testing which will result in the bow making loud cracks over time. This will eventually lead to a crack on the limbs.

- Are the limbs attached to the wooden Syah with just glue or also wrapped?

Without the wrap the “ends of your bows” can come apart from the main body and nobody wants that!

I think that is it for the Fibreglass. Let me know if I have missed anything!

What makes a Quality Wooden Bow

Everything that I have said about the fibreglass bows can also be applied to the wooden bows. This is because almost every laminated wooden bow made has a fibreglass finish to ensure durability and extra toughness to the elements.

- Therefore similarly to the other bows, if these have streaks on the glassing work in a vertical pattern, the materials and or the workmanship is not of a very high quality.

- Therefore similarly to the other bows, if these have streaks on the glassing work in a vertical pattern, the materials and or the workmanship is not of a very high quality.

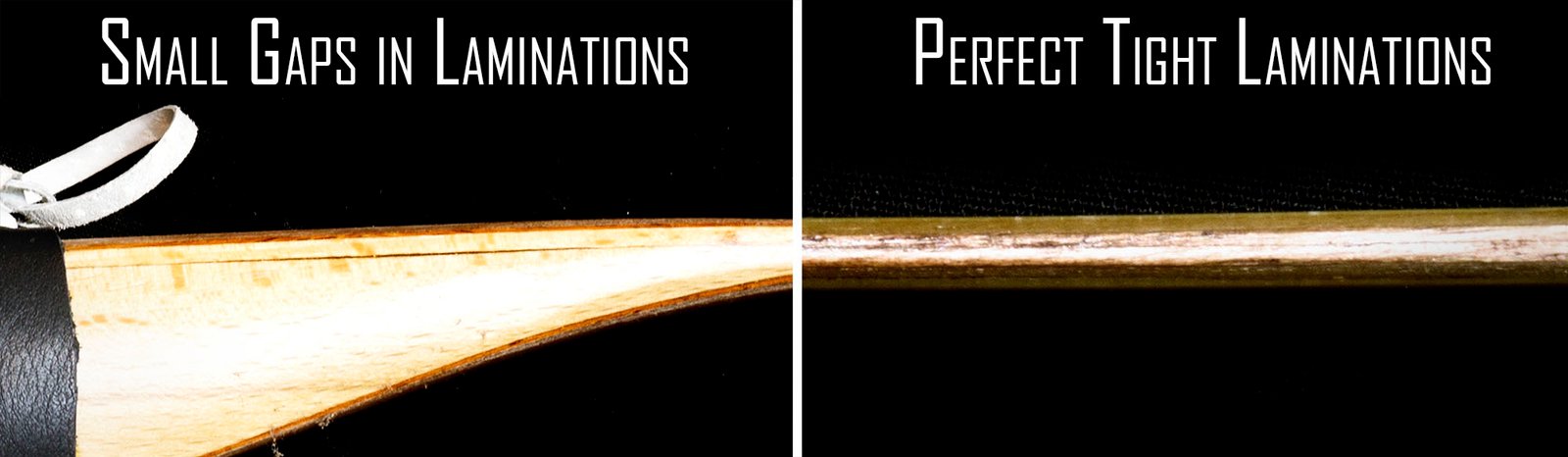

- If you look to the side of the bow at the laminations these should be very tight together and without large spaces like in the image attached. If there are spaces the bowmaker would have had to fill the gaps with resin which will weaken the bow and make it more likely to snap or delaminate.

- If you look to the side of the bow at the laminations these should be very tight together and without large spaces like in the image attached. If there are spaces the bowmaker would have had to fill the gaps with resin which will weaken the bow and make it more likely to snap or delaminate.

- Another small factor to look at is that the ends of the bow are spliced in a V shape into the lamination. If this is not done and it’s attached with a step method like in this image it can make a bow very weak.

- Lastly you should look at the finish of the bow. Is it smooth and soft to the touch or is it rough and very bumpy in the finish? If the latter then the bow maker placed the resin and sealer on without doing a fine sanding which leaves the bow in a more bumpy state. This is mainly aesthetic but it shows whether you are dealing with a quality bow maker or not.

With all of this said there is also one last major factor that will let you know weather a bow is well made or if it is a cheapy.

Obviously if the bow is $50 – $200 you may be able to shoot it. You may even enjoy it for a year or 2 but generally unless it was a giveaway or the bow maker was doing some clearing out the cost is too low. They can’t buy and make quality equipment at a price that low as it does take a lot of work and machinery/tools to create a bow. If you are interested in seeing how quality bows are made stay tuned for the next article about how they are made.

To quickly summarize the factors to look out for are :

- Quality of finish

- Quality of materials

- Quality of work

- Price

Thank you all for reading and Keep it traditional!

Very helpful, I’m looking at getting my first bow sometime soon. Cheers.